Food Service Temperature Monitoring Systems

24/7 Temperature Monitoring That Complies with HACCP Requirements

Percent of food lost or wasted in food service establishments 0

E-Control Systems (ECS) offers a complete IoT remote wireless temperature monitoring solution for the food service industry. Whether you are a school district, restaurant, processing plant, or operate any other food related business, we offer a fully automated enterprise-wide solution that makes it easy to monitor your entire food service operation and comply with HACCP requirements.

Temperature and time are the two most controllable factors for preventing foodborne illness.

How E-Control Systems Works for Food Temperature Monitoring

Monitoring food temperature and prioritizing compliance is a must in the food service world. With E-Control Systems you can view a snapshot of your entire operation 24/7 from any phone, computer, tablet, or device. As a leader in complete wireless temperature monitoring systems, E-Control Systems makes it easy to monitor food temperatures while reducing inventory loss and ensuring compliance with HACCP requirements. Invest more time doing what you do best, and let us help with the operations.

E-Control Systems Features for Food Service

What makes E-Control Systems stand out? Our sensors and Intelligates can monitor any aspect of your Food Service business 24/7.

What Sets Our Automated Food Service Monitoring Apart from Other Options in the Market?

E-Control Systems offers IntelliSense™ Wireless Temperature Monitoring System that allows food service businesses to monitor all cabinet/equipment temperatures and other critical control points required for HACCP record keeping. Whether you are in the kitchen, delivering catering, or relaxing at home – you can monitor operations effortlessly anywhere using our free App. Our technology doesn’t stop there. We also offer the IntelliCheck™ System which automates food temperature data logging and eliminates cumbersome form-based solutions.

With IntelliCheck™ you can monitor your entire cook-line food temperatures, from receiving, to storage, to cooking, to serving. Together, our technology delivers a complete HACCP and operation management system. The result? Improved food safety, inventory loss prevention, less work, and better compliance.

Our Food Industry Customers Include:

HACCP Temperature Monitoring Systems For Food Safety

School Cafeterias, Processing Plants, Restaurants & Kitchens

Our IntelliSense™ Wireless Temperature Monitoring System enables you to monitor all of your cabinet/equipment temperatures and other critical control points required for HACCP record keeping. Using our Patented Intelligent Sensor (U.S. Patent No. 9,064,389) and our free App for your iOS Apple and Android devices, you will be able to automatically and effortlessly monitor all of your equipment 24 hours a day, 7 days a week and receive alerts should any of your equipment readings fall out of range.

With ECS, you have the flexibility to monitor a wide array of items based on your custom applications, including but not limited to:

- Walk-In Coolers/Freezers

- Reach-in Coolers/Freezers

- Milk Coolers

- Holding Units (Hot & Cold)

- Under Counter Units

- Dishwasher Final Rinse Temperature

- Dry Storage

- Cold Storage

- Power Interruption

- Cook/Chill Units

- Food Temperatures

- Oven Temperatures

A variety of sensor types allows you to monitor not only temperatures but also humidity, door status, and other critical points. All data is stored in our secure cloud with server redundancy and automated system backups. Each sensor comes standard with data loggers, which will store data in case of a network or power outage. As soon as network/power is restored, the data loggers will transmit all of the data to the system. The system is battery-operated using wireless sensors that are easily installed, cost effective, and allow you to get up and running quickly.

Our IntelliCheck™ System is a complete HACCP food temperature monitoring system designed to automate food temperature data logging and eliminate cumbersome form-based solutions. With IntelliCheck™ you can monitor your entire cook-line food temperatures, from receiving, to storage, to cooking, to serving. The system works with a stainless steel probe and any iOS Apple device, including an iPod touch, iPhone, or iPad. With our free App, your entire operation can be monitored from the palm of your hand, and Corrective Actions, as well as the execution of Standard Operating Procedures (SOP), can be taken on the spot. Operators simply choose an option on their touchscreen and the IntelliCheck™ system does the rest.

By combining our IntelliSense™ and IntelliCheck™ product lines, you receive a complete HACCP and operation management system, which comes standard with Preventative Maintenance and Asset Management modules. The result is a cost effective, easily installed solution that simplifies HACCP compliance, improves food safety, prevents inventory loss, and ultimately reduces your overall workload.

E-Control Systems Allows Your Food Service Establishment to:

- Access Temperature Data Anytime, and from Anywhere.

- No more waiting for temperature readings.

- Receive instant alerts so you can nip any problems in the bud.

- Skip the human error factor.

- Ensure more robust compliance at every step.

The Importance Of Time With Food Safety Temperature Monitoring

When monitoring the temperatures of equipment and food products in your operation, time is an important factor in ensuring food safety. The FDA specifies how long food is considered to be in the “safe zone.” You should have a HACCP plan in place that will help you avoid costly product loss by making sure that you have enough time to move your food, should any of your equipment start failing.

When monitoring the temperatures of equipment and food products in your operation, time is an important factor in ensuring food safety. The FDA specifies how long food is considered to be in the “safe zone.” You should have a HACCP plan in place that will help you avoid costly product loss by making sure that you have enough time to move your food, should any of your equipment start failing.

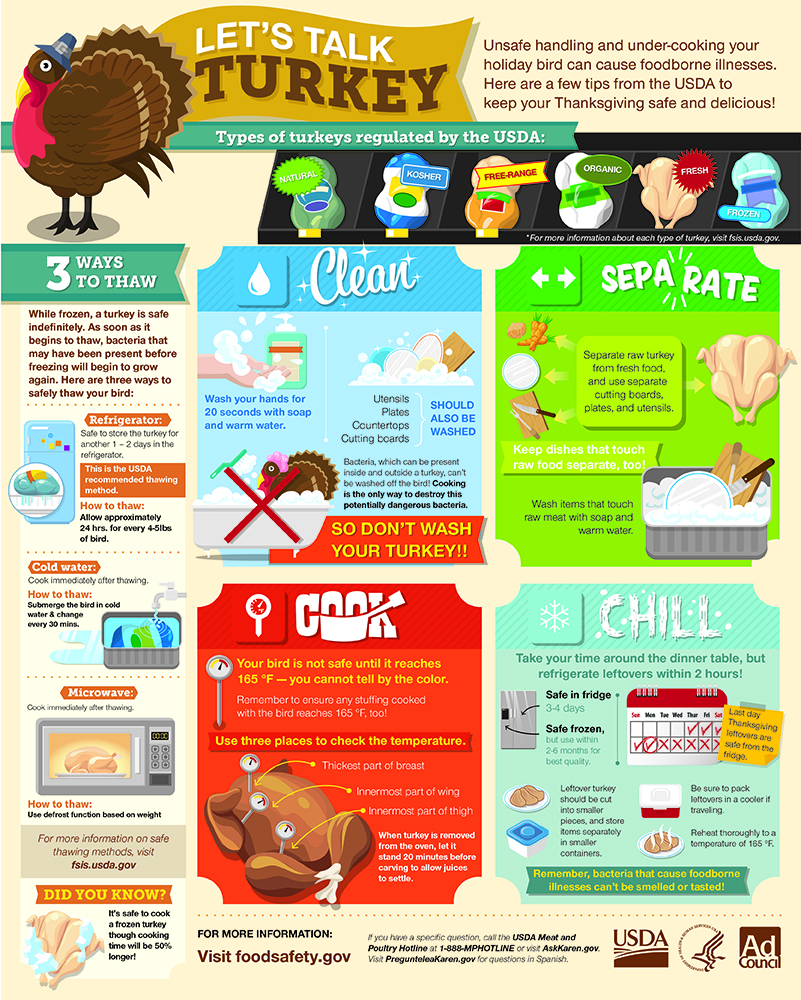

When heating food, the food must reach and maintain a certain temperature for a specified amount of time.In a cook and chill operation, there are strict time requirements. Food not only has to be chilled to the approved temperature range, but it has to reach that temperature in a specific amount of time, as per FDA guidelines. The FDA considers the Danger zone to be 40 °F to 140 °F, as this is the temperature range where most bacteria can grow. Foods that are exposed to this temperature range for more than 4 hours at a time are considered not safe for consumption. Measuring time, as well as temperature, will enable you to comply with FDA guidelines for food safety.

Having a wireless temperature monitoring system will ensure that your food/equipment is in an acceptable HACCP temperature range, and will also alert you when your food/equipment goes out of the acceptable range and for how long. Besides monitoring temperature, your HACCP plan should include a time element, as it is one of the important Critical Control Points. Any temperature monitoring system must be able to help automate all your HACCP requirements, thus minimizing downtime and the chance of bacteria growth.

Remember, when it comes to temperature monitoring and food safety, time is of the essence!

Food Temperature Monitoring FAQ's

At ECS, we provide food safety and storage temperature monitoring for the following industries:

- Schools

- Restaurants

- Food Processing & Production Plants

- Grocery Stores

- Convenience Stores

- Cafeterias

- Commercial Refrigeration

- Refrigerated Trucks & Trailers

- Wine Storage

- And more

What is a Food Temperature Monitoring System?

A food temperature monitoring system is a technology-enabled system that is designed to help food service providers and other professionals monitor and control the temperature of food products during various stages of the food handling process. This can include food storage, transportation, cooking, and serving.

Our E-Control System (ECS) for food service temperature monitoring consists of a complete wireless HACCP temperature monitor. For food service professionals this means the capability to monitor multiple systems from one place (yes, you can monitor from your smartphone). So, how does it work?

A variety of sensors, data loggers, and software that work together to collect and analyze data on the temperature of food products. The sensors are placed inside refrigerators, freezers, ovens, and other food storage and cooking equipment to monitor the temperature in real-time. The data loggers store all data collected by the sensors and transmit it to an ECS secure cloud with server redundancy and automated system backups.

Our ECS software then provides alerts and notifications to you if the temperature of the food products falls outside of safe levels. This helps to prevent food spoilage, reduce waste, and minimize the risk of foodborne illness. ECS also provides analytics and reporting features, which enable you to track and analyze temperature data over time, identify trends, and make more informed decisions about food safety and quality.

Our E-Control System (ECS) for food service temperature monitoring consists of a complete wireless HACCP temperature monitor. For food service professionals this means the capability to monitor multiple systems from one place (yes, you can monitor from your smartphone). So, how does it work?

A variety of sensors, data loggers, and software that work together to collect and analyze data on the temperature of food products. The sensors are placed inside refrigerators, freezers, ovens, and other food storage and cooking equipment to monitor the temperature in real-time. The data loggers store all data collected by the sensors and transmit it to an ECS secure cloud with server redundancy and automated system backups.

Our ECS software then provides alerts and notifications to you if the temperature of the food products falls outside of safe levels. This helps to prevent food spoilage, reduce waste, and minimize the risk of foodborne illness. ECS also provides analytics and reporting features, which enable you to track and analyze temperature data over time, identify trends, and make more informed decisions about food safety and quality.

How Do You Track Food Temperature?

Temperature and time are the two most controllable factors for preventing foodborne illness. With this in mind, proper food temperature regulation is at the top of food safety priorities and protocol. With ESC food service monitoring system, tracking your food temperature is as easy as it has ever been.

Our completely wireless temperature monitoring system uses sensors to monitor food temperatures in real-time. The data collected by the sensors is transmitted wirelessly to a central monitoring system, which can be accessed remotely through your computer or mobile device.

It’s important to ensure that food is stored, cooked, and served at the correct temperature to prevent the growth of harmful bacteria and reduce the risk of foodborne illness. ESC eliminates the unnecessary hassle, making your life easier and your food safer, not to mention, the extra layer of protection it offers any business responsible for serving food.

What Are the Benefits of Food Monitoring Systems?

There are incredible benefits to implementing a HACCP temperature monitoring system powered by ECS. Top benefits can include:

- Improved food safety: One of the most significant benefits of food temperature monitoring is improved food safety. Proper temperature control is essential for preventing the growth of harmful bacteria that can cause foodborne illness. Monitoring food temperature helps to identify and address any potential issues before they become a food safety hazard.

- Reduced food waste: Monitoring food temperature can also help to reduce food waste. When food is stored or cooked at the wrong temperature, it can spoil more quickly, leading to waste. By ensuring that food is kept at the correct temperature, food waste can be minimized.

- Cost savings: In addition to reducing food waste, food temperature monitoring can also lead to cost savings. When food is stored and cooked at the correct temperature, it’s less likely to spoil, reducing the need to throw away food and replace it.

- Compliance with regulations: Many food service providers are required to comply with regulations related to food safety and temperature control. Implementing a food temperature monitoring system can help to ensure compliance with these regulations and prevent potential fines or penalties.

- Improved customer satisfaction: Serving safe and high-quality food can help to improve customer satisfaction and loyalty. By monitoring food temperature and ensuring that food is stored and served at the correct temperature, food service providers can deliver a better overall experience for their customers.

What Equipment Would You Use to Monitor the Temperature of Food Products and Their Environment?

There are various types of equipment that can be used to monitor the temperature of food products and their environment, depending on your specific needs. Here are some common examples:

- Thermometers: Digital, dial, or infrared thermometers are commonly used to measure the temperature of food products. They are inserted into the thickest part of the food to obtain an accurate reading.

- Data loggers: These are devices that can record and store temperature data over time. They can be used to monitor the temperature of refrigerators, freezers, and other storage areas to detect temperature fluctuations.

- Wireless temperature monitoring systems: Like our ECS system, these systems use wireless sensors to monitor food temperatures in real-time. The data collected by the sensors is transmitted wirelessly to a central monitoring system, which can be accessed remotely through a computer or mobile device.

- Temperature-sensitive labels: These adhesive labels change color when the temperature of the food exceeds a certain threshold. They are often used on packaged foods, such as meat and dairy products, to indicate whether the food has been stored or transported at safe temperatures.

- Infrared cameras: Infrared cameras can be used to monitor the temperature of cooking equipment, such as ovens and grills, without the need for physical contact with the food.

- Probe wipes: These are disposable wipes that can be used to sanitize thermometers and other temperature monitoring equipment between uses to prevent cross-contamination.

- Temperature-controlled transport containers: These are insulated containers that are designed to maintain the temperature of food during transport. They are often used in the foodservice and catering industries to transport hot or cold food safely.

By using a combination of these tools, you can ensure that food products are stored, cooked, and served at the correct temperature to prevent foodborne illness and maintain the quality of the food.

What Can You Monitor in Food Service?

In food service there’s a lot to monitor, from the quality of raw foods to cleanliness to serving perfectly prepared dishes. While you’ll need to find ways to monitor as much as you can, as best as you can, here are some things you can monitor in food service:

- Food temperatures. With the HACCP temperature monitoring system, food temperature is essential for ensuring that food is stored, cooked, and served at the correct temperature to prevent the growth of harmful bacteria that can cause foodborne illness.

- Equipment temperatures. Monitoring the temperature of cooking equipment, such as ovens, grills, and fryers, can help to ensure that food is cooked to the correct temperature and maintain the quality of the food.

- Sanitation. Monitoring the cleanliness of food preparation areas, equipment, and utensils is essential for preventing cross-contamination and the spread of harmful bacteria.

- Food quality. Monitoring the quality of food products, such as freshness, flavor, and texture, can help to ensure that customers are satisfied with their meals and maintain loyalty.

- Inventory management. Monitoring inventory levels and usage can help you minimize waste, reduce costs, and ensure that they have the necessary ingredients and supplies to prepare meals.

- Customer feedback. Monitoring customer feedback, such as reviews and surveys, can help you identify areas for improvement and make changes to meet customer expectations.

By monitoring these aspects of food service, you can ensure that you’re providing safe, high-quality food that meets the needs and expectations of your customers.

What is GMP?

GMP stands for Good Manufacturing Practice. It’s a set of guidelines and procedures designed to ensure that food products are consistently produced and controlled in a manner that meets quality and safety standards.

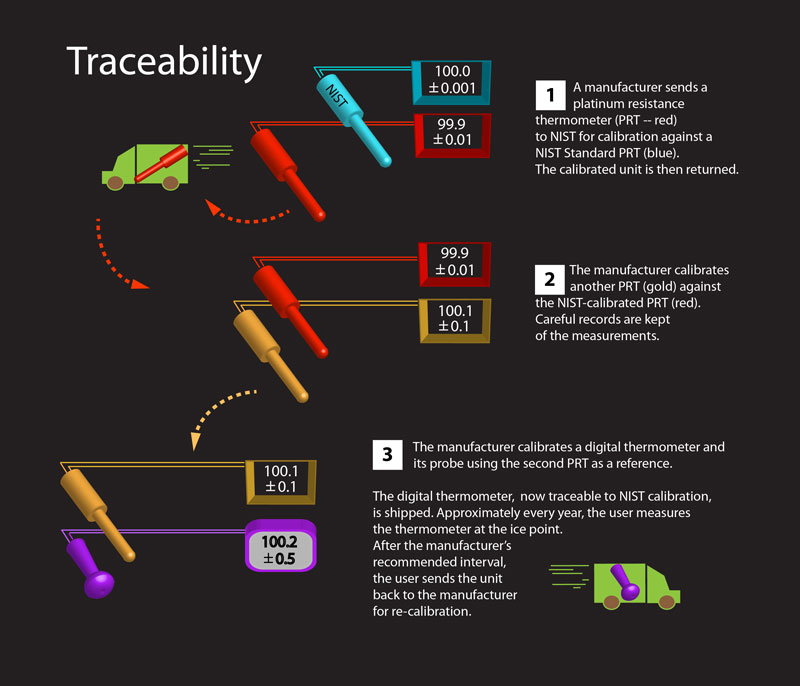

GMP guidelines cover all aspects of food production, including the design and construction of facilities, equipment maintenance and calibration, employee training and hygiene, and record-keeping. The goal of GMP is to prevent contamination, cross-contamination, and other errors that can lead to unsafe food products.

GMP is widely used in the food industry and is required by many regulatory agencies, such as the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in the European Union. Compliance with GMP guidelines is often monitored through inspections and audits to ensure that food production facilities are operating in a safe and efficient manner.

Is Temperature Monitoring a Legal Requirement for Food Service?

Yes, absolutely. Temperature monitoring is a legal requirement for food service in many countries, including the United States, Canada, the United Kingdom, and the European Union.

As a food service provider, you’re required to monitor the temperature of food products to ensure that they’re stored, cooked, and served at safe temperatures to prevent the growth of harmful bacteria that can cause foodborne illness.

Regulatory agencies, such as the FDA in the United States, provide specific guidelines for temperature monitoring in food service, including the use of calibrated thermometers and temperature recording devices, as well as requirements for the frequency of monitoring and the corrective actions to be taken in the event of temperature deviations.

If you fail to comply with temperature monitoring requirements you may be subject to legal penalties, including fines, loss of operating licenses, and legal action by customers who become ill as a result of consuming unsafe food products.

ECS’ technical innovations have been driven by the desire to meet the ever-changing market needs and increasing regulatory requirements related to monitoring of food, drugs, manufacturing processes and controls (including HACCP, The Joint Commission, AABB, GLP/GMP, FCC, and FDA). Never be caught unaware or uninformed regarding your food service temperature monitoring system. ECS provides food safety and storage temperature monitoring for schools, restaurants, food processing and production plants, grocery stores, convenience stores, cafeterias, and much more.

At ECS, we provide food safety and storage temperature monitoring for the following industries:

- Schools

- Restaurants

- Food Processing & Production Plants

- Grocery Stores

- Convenience Stores

- Cafeterias

- Commercial Refrigeration

- Refrigerated Trucks & Trailers

- Wine Storage

- And more

How does an automated temperature monitoring system improve accuracy compared to manual checks?

Manual readings are inconsistent because they depend on employees to remember, record, and interpret temperatures. When a cooler fails between manual checks, it may go unnoticed for hours, and food spoilage will occur. Our E-Control Systems IntelliCheck™ System automates temperature data to continuously catch all deviations that can compromise food safety and eliminates manually written data. You and your staff can access the temperature data from anywhere at any time.

What makes kitchen temperature monitoring critical during busy service hours?

Kitchen temperature monitoring ensures ingredients stay within safe ranges, preventing bacterial growth and reducing the risk of foodborne illness. This protects guests, prevents equipment from failing, ensures restaurant staff follow safe protocols, and protects the restaurant's reputation. You can conveniently monitor food temperatures using E-Control Systems FusionLive dashboard 24/7.

Can food industry temperature monitoring systems be customized for different types of equipment?

Food temperature monitoring systems can be outfitted with interchangeable steel probes and wireless sensors, allowing one system to serve multiple cooking stations without compromising safety or accuracy. The E-Control Systems FusionLive dashboard and alerts can be customized to manage the temperature of each operation and to comply with HACCP regulations.

What are the cost savings of investing in a food temperature monitoring system?

Predictive food industry temperature monitoring systems are able to detect subtle temperature fluctuations signaling equipment potential breakdowns before they occur. This helps food businesses avoid expensive emergency services and reduces disruptions and downtime. They also have the capability to streamline recordkeeping and create digital reports, to avoid fines and failed inspections.

What types of food service equipment can temperature systems monitor?

- Walk-In Coolers and Freezers

- Reach-in Coolers and Freezers

- Milk Coolers

- Hot and Cold Holding Units

- Under Counter Units

- Dishwasher Final Rinse Temperature

- Dry Storage

- Cold Storage

- Power Interruption

- Cook or Chill Units

- Food Temperatures

- Oven Temperatures

Do automated food service monitoring systems work during power outages?

E-Control Systems food service monitoring systems are web and app-based and can be used with cellular service so alerts can be transmitted 24/7 via mobile data. Each sensor is equipped with data loggers that store your data during power outages and restore it when the power outage ends. Whether you need to move inventory, dispatch staff, or activate a backup generator, the data will show a complete audit trail of when the outage occurred, how long it lasted, and if any temperatures reached unsafe levels. This information can be critical for insurance claims and HACCP compliance.

How does a food safety monitoring system support HACCP compliance long term?

Our wireless food safety monitoring system creates a digital log about what’s happening in your facility. You can monitor everything from storage to cooking to serving, preventing inventory loss and complying with HACCP regulations. Our system makes it easier to adjust your HACCP plan to ensure food safety and prevent risks. Track performance, access live data, and system alerts from your smartphone so you stay informed and in control of your business operations.